Industrial infrastructure must be designed to handle both routine operations and unexpected disruptions. This requires components that are not only efficient but also adaptable under pressure. The air and manual actuator is one such component—providing a combination of automated control and manual functionality that enhances both resilience and reliability.

Air-powered actuators are commonly used across sectors such as wastewater management, energy production, and food processing. Their ability to perform quick, clean, and repeatable valve operations makes them ideal for automation. However, reliance on automation alone can be risky. When control systems go offline or air supply is interrupted, operations can stall—unless there’s a manual backup in place.

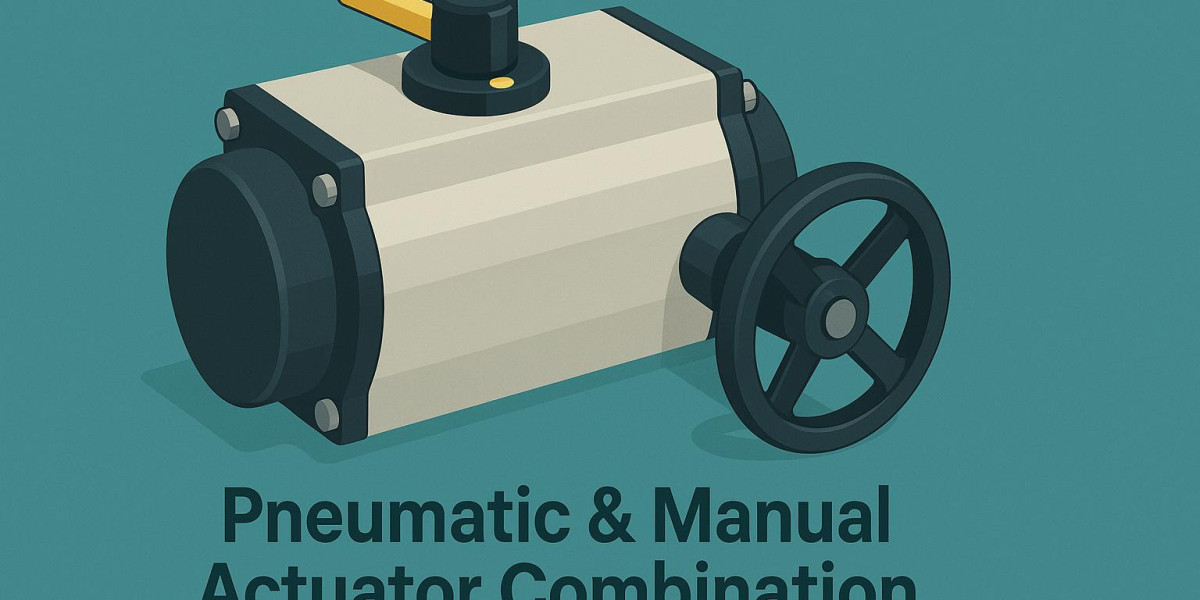

An air and manual actuator integrates a manual override feature directly into its design. This allows operators to take control manually without needing to disassemble or bypass the actuator. In critical moments—such as during emergencies, maintenance work, or system troubleshooting—this functionality ensures uninterrupted access to valve control.

The inclusion of a manual mode also simplifies maintenance routines. Technicians can manually actuate components to test system responses or isolate lines for inspection, all without requiring external tools or additional equipment. This boosts operational efficiency while ensuring safety.

Furthermore, the integrated design reduces the need for separate manual gearboxes or auxiliary devices, which in turn minimizes space usage and installation complexity. The result is a streamlined system architecture that is easier to manage and maintain.

Durability is another hallmark of these actuators. Built to withstand harsh industrial environments, they often feature corrosion-resistant materials and rugged construction that extends their service life and reduces replacement frequency.

In short, air and manual actuators are more than just a backup—they are a strategic investment in process continuity and infrastructure reliability. By offering dual-mode control, they help ensure that your systems stay operational and safe, regardless of what challenges arise.